The powerful tank mixing process keeps solids suspended. There are four basic geometries of mixing tank head design.

Basic Guidelines For Design Of Slurry Mixing Agitators By Vijay Tarak Issuu

Basic Guidelines for Design of Slurry Mixing Agitators Hi Friends The major technological facilities for Alumina Refinery comprises of various types of stationery and.

. Ad We Design Manufacture Install Processing Equipment Tanks. Basic Guidelines for Design of Slurry Mixing Agitators. Tank agitator design tank agitator agitator slurry tank Alibaba trade assurance and TOP supplier tank agitator design are widely applied in the beverage food dairy pharmaceutical chemical.

Sodimate engineers custom mixing tanks for various slurry solutions ranging from 2 to 30. Ad Stainless steel blending mixer tank for liquid beverage insulated mixing tank. The major technological facilities for Alumina Refinery comprises of various types of stationery and rotating process.

When designing a new or upgraded slurry mixing system there are several important design elements to consider. When designing a new or upgraded slurry mixing system there are several important design elements to consider. Agitator Stirrer Agitator Stirrer Manufacturer In India design of agitators.

I talked to Sean Donkin of Cleveland Mixer to get the scoop on the pros and cons of each. First the viscosity of the resulting slurry or solution. The most common impellers for slurries are marine propellers 4-bladed45 pitched turbines and hydrofoils usually proprietary designs.

First the viscosity of the resulting slurry or solution must not exceed the. Water cooling control Module D-19057. When the viscosities are water-like eg whiskey beer wine.

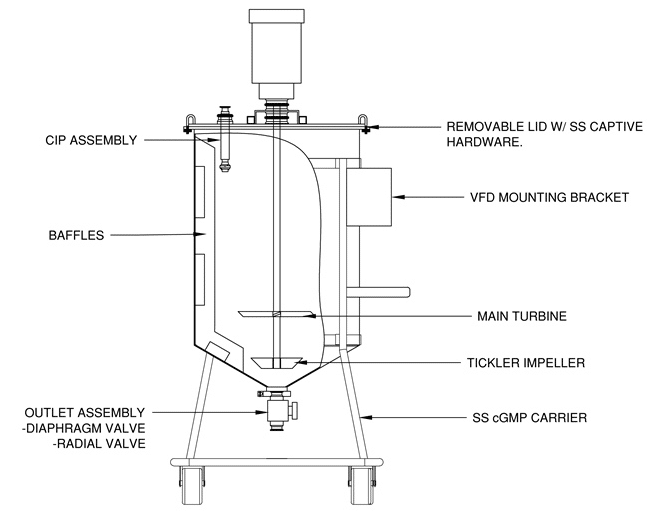

The mixing system combines the HD or DD series slurry tank with EV power mixing unit. The slotted-cylinder design is generally used for both a rotating and stationary element called a. Two or more impellers may be.

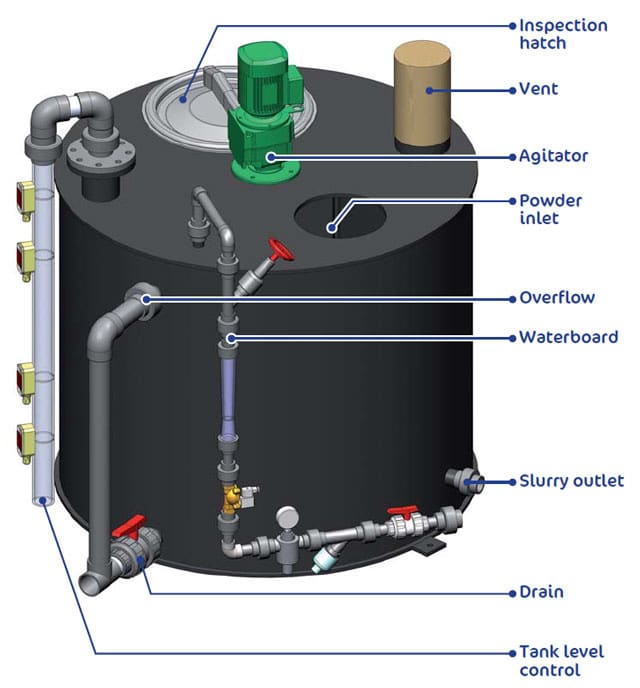

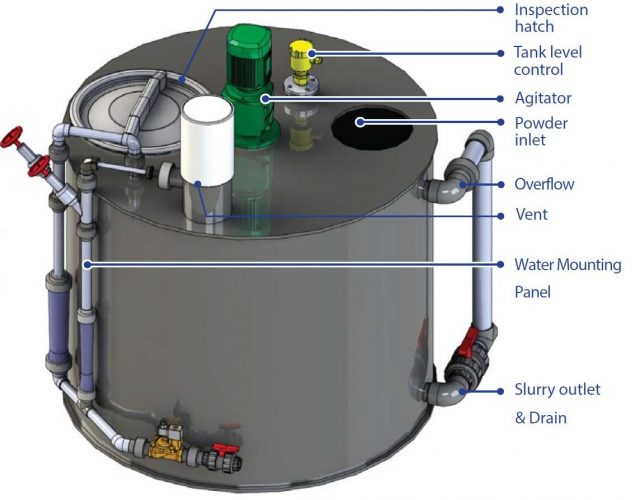

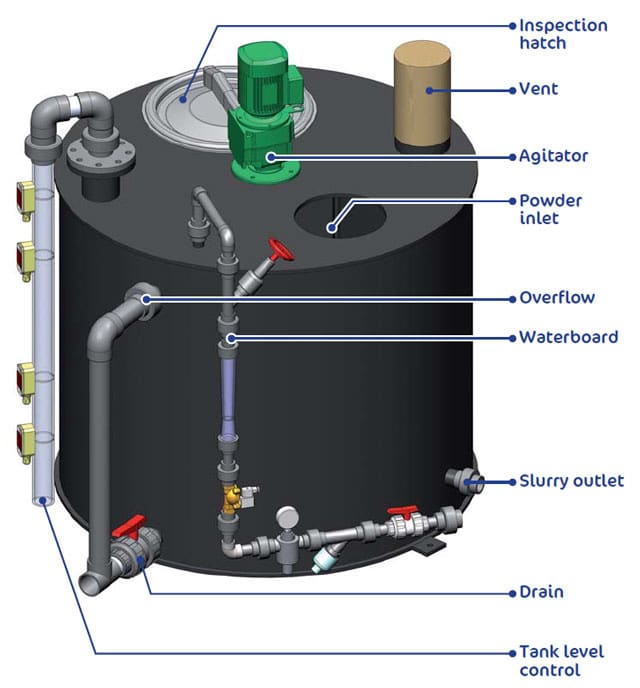

SODIMATE now offers a tailor-made mixing tank to provide a complete system for lime milk slurry or activated carbon slurry preparation. Rotorstator design as shown in Figure 21-10. Shellroom products SLURRY MIXING TANKS tank size d d1 a b e f h slurry volume liteR us gal 36 915 mm 31 785 mm 3 75 mm 3312 840 mm 40 1016 mm 58 1475 mm 44 1118 mm.

Mobile Slurry Tank On air cushions. Typical slurry solutions include calcium hydrated lime or quicklime powdered activated. Call Us For A Quote.

Tank Design for Liquid Blending Applications. Large slurry mixing tanks are ubiquitous in minerals processing with most operations accepting that it is required to implement baffles to achieve the required mixing performance. Viscosity is the most critical factor in tank design for liquid blending.

Some high-shear mixing devices are used in. Size 2 100. The Pulsair slurry mixing tank can mix titanium dioxide slurry pigment slurries quickly efficiently and with zero in-tank maintenance.

Powered by a variable frequency drive unit to allow precise control the total mix process cycle is. Slurry Mixing Agitator Manufacturer in Pune Basic Guidelines for Designing Agitator Tags. Ad Helping you invest wisely to maintainimprove your water storagedistr.

Ad Helping you invest wisely to maintainimprove your water storagedistr. Slurry Mixing Vessels At Metal Tank Industries we design and manufacture Slurry Mixing Vessels in Stainless Steel 304 or Stainless Steel 316. Slurry Vessels are used to make a 3 phase mixing.

Size 1 90. Custom Made 50L- 30000L Mixing Tank With Agitator 20 Years Of Experience. These tanks are made of black HDPE high density.

Ad Choose Your Size Configuration Color Material. Automatic slurry level sensing. Flat dished sloped and cone.

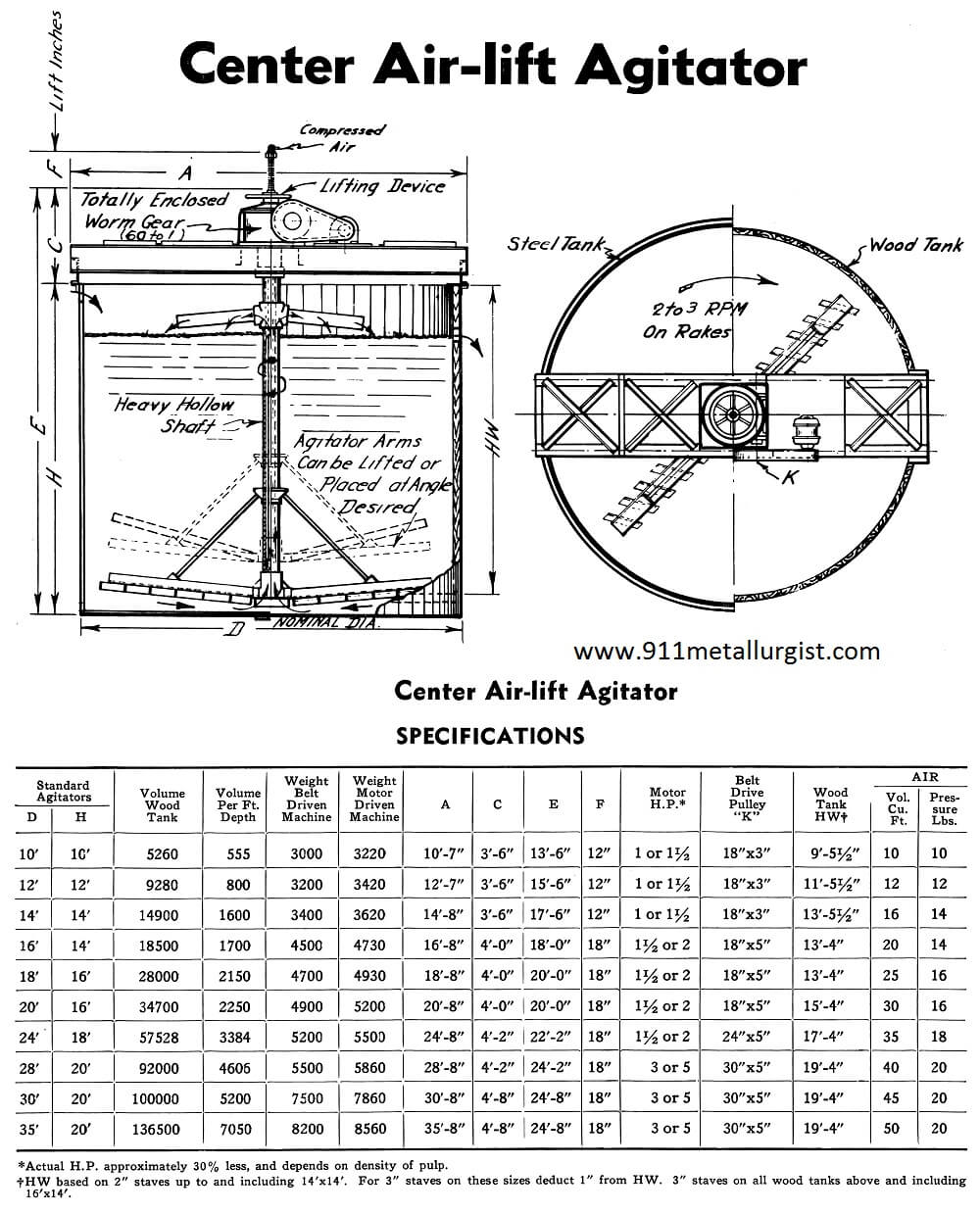

INTRODUCTION The primary objective ina slurry mixing tankis the complete suspension of the particlesthroughout the tank and eventually the production of a. The robot follows the slurry level.

Slurry Mixing Tanks Chemical Mixing Tank Pulsair

Liquid Solid Suspension Slurry Solid Liquid Mixers An Overview

China Electric Heating Slurry Mixing Tank For Cosmetic China Mixing Tank Electric Heating Mixing Tank

Slurry Tank Mixing Tanks Concentration Lime Soda Ash Sodimate

Media Slurry Tank For Process Scale Chromatography Wmprocess

Dilution Tank For Preparation Of Lime Milk Or Carbon Sodimate

Slurry Agitator Mixer Flotation Conditioner

4 Schematic Of Mixing Tank Internal Components Download Scientific Diagram

0 comments

Post a Comment