Toluene is stored in mild steel or stainless-steel tanks. Pressure vessel design Stress analysis of piping structural design ASME Joint review Design of Storage tanks code calculations FEA and spotless service on design management.

Toluene Storage Tank Parameters Download Scientific Diagram

The blended mixture enters a storage tank inner diameter 55 m.

. TOLUENE Tank Chemical Compatibility of common Resins Fittings Gaskets and Metals RESINS. Atmospheric storage tanks can be further broken down into open top storage tanks fixed roof tanks and floating roof. Atmospheric Above Ground Tank Storage of Methanol INTRODUCTION Guidelines for designing fabricating constructing repairing and safeguarding above-ground methanol storage tanks is essentially the same as that for liquid transportation fuels such as ethanol and gasoline and flammable liquid feed stocks such as benzene acetone and toluene.

The most effective primary tank seals with respect to reducing emissions. During its storage and as a result of changes in the liquid level. The design is based on a polymer fabric reinforced cover around a resilient foam core being held down by steel plates.

Here is how TOLUENE works with plastics used to make our TOLUENE storage tanks. Outside or detached storage preferred. 5 atm 40 C H.

The temperature of the contents must be above 60 degrees F or 16 degrees C when the car is unloaded. Toluene storage is highly flammable and has the ability to catch fire if exposed to heat sparks or flames. Design and Construction of Large Welded Low-Pressure Storage Tanks and API Standard 650 Welded Steel Tanks for Oil Storage.

Analysis on Risk of Multi - factor Disaster and Disaster Control in. Proper equipment design and handling procedures maintain low risk from exposure to toluene where the product is used as a. For this reason atmospheric storage tanks are the ones that are best suited for storing crude oil.

Don1980 Chemical 24 Jun 21 2226. Emissions from fixed roof tanks are a result of evaporative losses during storage known as breathing losses or standing storage. Toluene storage tank T-351 and styrene tanks T-352A through C have storage capacities of 30 days each.

Under certain circumstances ßame arresters listed by the UnderwritersÕ Laboratories or approved by the Factory Mutual Engineering and Research Corporation are used in conjunction with or in lieu of a pressure. According to NFPA 704 toluene risks include. External floating roof internal floating roof aboveground vertical fixed roof aboveground horizontal fixed roof and underground storage tanks Storage t ank emissions associated with each design are briefly described here.

Calculate the flow rate of toluene into the blender Lmin and the composition of the tank contents wt benzene. Toluene is typically shipped in insulated tank cars equipped with external heating coils and a safety relief valve set for 75 psi. Pressurised storage tanks are usually used for storing liquids that evaporate.

There are five basic designs for organic liquid storage tanks. Toluene tank and nitrogen pad. 25 Full PDFs related to this paper.

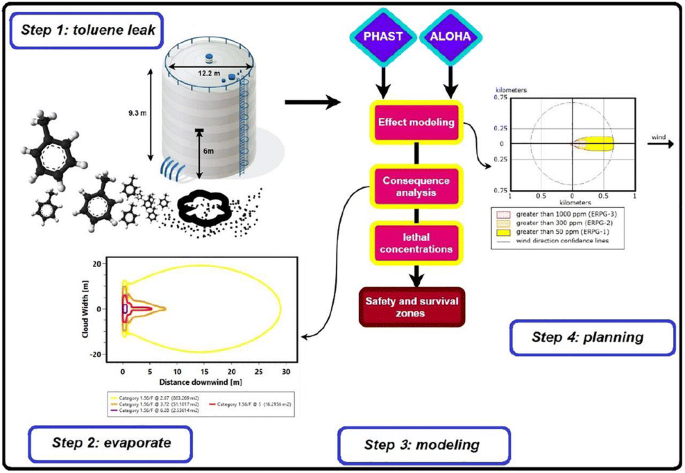

Ergo the effects and consequences of toluene leaks can be modeled and quantified to aid in emergency planning and response management. A short summary of this paper. Toluene is transported by tank truck rail car.

2 Tank design and key components 21 General design philosophy Tanks are designed using the following criteria unless otherwise agreed. Universal Engineerings professional design engineering services wing offers design and detail engineering services provide detailed design and engineering services. A typical fixed-roof tank consists of a cylindrical steel shell with a cone- or dome-shaped roof that is permanently affixed to the tank shell.

Store in a cool well-ventilated area. If needed the tank car can be heated to 68 degrees but do not exceed 104 degrees F or 40 degrees C. As the seal is very flexible it contacts the tank shell in an extended area which provides excellent vapour tightness of the rim space.

Up to 10 cash back Abstract. Tank panels and components can also be epoxy coated to meet particular aesthetic site requirements. The container choice for example storage vessel may effect static accumulation and dissipation.

Exposure to toluene can affect color vision hearing and high concentrations of exposure can lead to tiredness difficulty sleeping numbness in limbs and damage to reproductive systems. Handle containers with care. Storage containers should be grounded and bonded.

Download scientific diagram Toluene storage tank parameters from publication. Foam manufacturer chemical storage vent system technical evaluation The client manufactures foam products at a southeastern US. One may choose to tolerate a flammable atmosphere inside the tank and prevent ignition by use of a flame arrester.

This facility currently receives toluene diisocyanate TDI in tank trucks and performs a pressure-assisted pump offloading procedure whereby the material is transferred into a bulk material tank farm. As you know ignition of flammable vapors inside a tank must be reliably prevented. 14 l System Boundary.

The emission sources vary with tank design as does the relative contribution of each type of emission source. This study modeled the effects and consequences on various scenarios of toluene release via. Handbook of Storage Tank Systems - Codes Regulations and Designs.

Full PDF Package Download Full PDF Package. But how thats accomplished is up to the tank owner. Guidelines for designing fabricati ng constructi ng repairing and safeguarding above-ground methanol storage tanks is essenti ally the same as that for liquid transportati on fuels such as ethanol and gasoline and fl ammable liquid feed stocks such as benzene acetone and toluene.

During an interval in which no liquid leaves the storage tank the liquid. Manufacture storage product transfer transportation and customersmarkets. The most effective way to reduce the environ- mental and safety concerns with the storage and handling of hazardous chemicals is through the proper engineering design and selection of the correct materi- als of construction for your chemical storage and handling systems.

Level in the tank is observed to increase by 015 meters over a one-hour period. The leakage of toluene from damaged tanks can threaten both workers and the environment. Storage tanks are usually fully welded and designed for both liquid and vapor tight while older tanks are often have a riveted or bolted construction and are not vapor tight.

The design fabrication and installa- tion of the primary storage vessels piping systems and. However physical and chemical properti es of meth-. W Tank shell is designed to accommodate full hydraulic load minus the free-board w Wind speed of 45 ms tank.

High Temperature Polymers Toluene from recycle toluene storage tank T-404A or B and make-up toluene from toluene storage tank T-201A or. 2 MCH TOL C. Atmospheric tanks are operated at or near the pressure found in the atmosphere.

Open slowly in order to control possible pressure release. 14 g 350 C PSA To Burner Tailgas 12 atm MCH 100 255 C 256 kWth. Purification Compression 2 atm Dehydrogenation 20 atm Storage 1 PSA Tailgas NG High grade waste heat Storage 2.

TOL 95 Okada Y. MCH Tank TOL 100 Toluene Tank H. 70 C 250 C.

Toluene C7h8 Handling Design Loading And Installation Saferack

Toluene C7h8 Handling Design Loading And Installation Saferack

Toluene C7h8 Handling Design Loading And Installation Saferack

Toluene Storage Tank Parameters Download Scientific Diagram

Floating Roof Tank Seal Internal External Floating Roof Tanks Comparison Anson

Toluene Storage And Safe Handling Practices In Your Facility

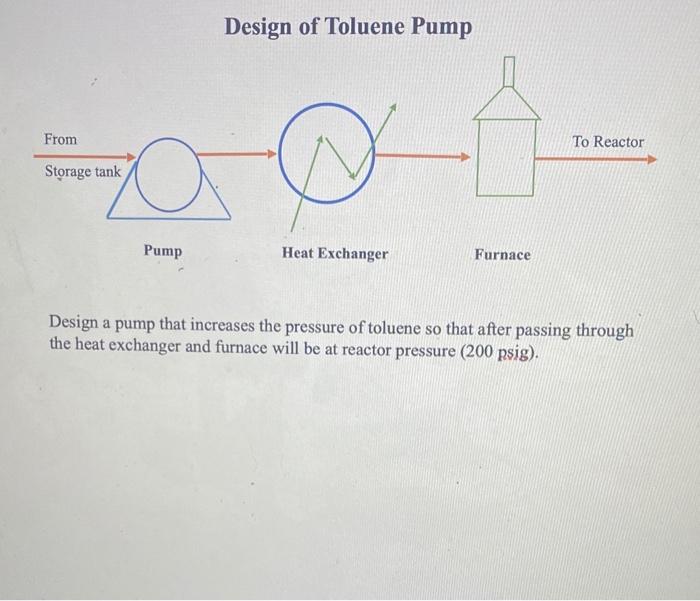

Solved Design Of Toluene Pump From To Reactor Storage Tank Chegg Com

Hazards Of Toluene Storage Tanks In A Petrochemical Plant Modeling Effects Consequence Analysis And Comparison Of Two Modeling Programs Springerlink

0 comments

Post a Comment